The perfect combination of high-performance crushing cavity type and high crushing frequency greatly improves its processing capacity, and because of the lamination crushing principle, the crushed products are mostly cubic structures, which greatly reduces needle-like materials.

When working, the motor drives the eccentric sleeve to rotate through the V-belt, the large pulley, the transmission shaft, the small bevel gear and the large bevel gear, and the axis of the crushing cone rotates and oscillates under the force of the eccentric bushing, so that the surface of the crushing wall sometimes approaches. From time to time, it leaves the surface of the rolling mortar wall, so that the material is continuously impacted, squeezed and bent and broken in the annular crushing cavity composed of the fixed cone and the moving cone.

High reliability and good stability

High reliability and good stability: The automatic control system with large diameter spindle, heavy main frame and independent thin oil lubrication system ensures the equipment is durable and reliable in operation. The iron-passing protection device ensures that the original discharge port can be quickly restored after the miscellaneous iron passes through the crushing cavity to ensure the discharge size.

Easy maintenance and easy operation

Easy maintenance and easy operation: no fillers mechanically lock the wearing parts, easy to replace, save time and effort, and greatly save the investment cost of customers.

Low operating cost Wide range of applications

Low operating cost and wide application range: due to large production capacity, high reliability and convenient maintenance, the production cost is greatly reduced; the machine adopts the principle of lamination and crushing to form a protective layer of material layer, which not only effectively reduces wear and prolongs the service life of wearing parts , and the proportion of cubes in the product is significantly increased, and the particle size is more uniform.

Simple structure and stable operation

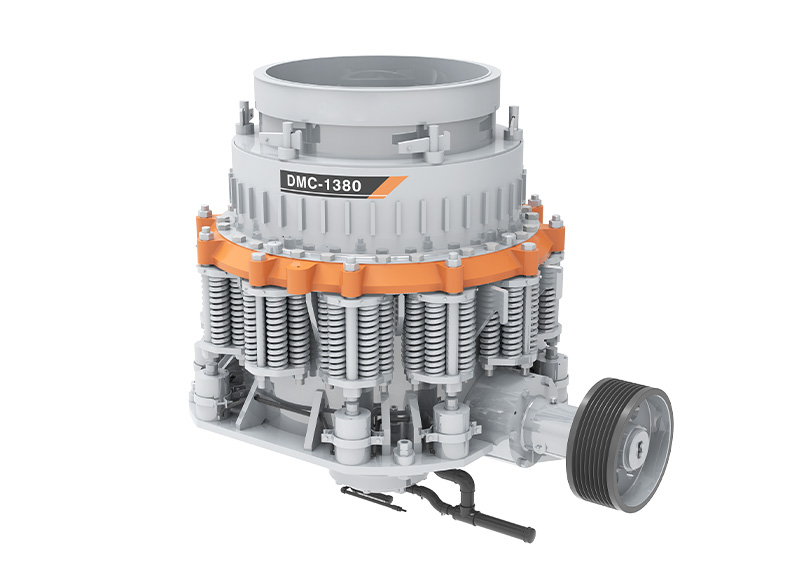

Simple structure and stable operation: DMC compound cone crusher is simple in structure, easy to operate and maintain, convenient and quick to adjust the discharge port, time-saving and labor-saving during maintenance, especially the lining plate is easy to quickly replace, which reduces the downtime.

Technical Parameter

| Model | Chamber | Max. feed size (mm) | Min discharge opening (mm) | Motor power (kw) |

Capacity (t/h) Closed side setting (mm) |

Weight(t) | |||||||||

| 6 | 10 | 13 | 16 | 19 | 22 | 25 | 38 | 51 | 64 | ||||||

| DMC1000 | C | 160 | 13 | 110 | 80 | 100 | 135 | 150 | 175 | 235 | 10.8 | ||||

| M | 115 | 10 | 110 | 65 | 75 | 90 | 120 | 135 | 150 | 10.8 | |||||

| F | 80 | 8 | 110 | 52 | 62 | 72 | 78 | 115 | 10.51 | ||||||

| EF | 50 | 6 | 110 | 50 | 55 | 65 | 70 | 102 | 10.51 | ||||||

| DMC1160 | C | 180 | 13 | 132 | 115 | 135 | 150 | 180 | 200 | 260 | 15.5 | ||||

| M | 130 | 10 | 132 | 100 | 110 | 120 | 135 | 165 | 175 | 15.5 | |||||

| F | 90 | 10 | 132 | 80 | 105 | 110 | 140 | 15.5 | |||||||

| EF | 60 | 6 | 132 | 60 | 74 | 105 | 110 | 130 | 15.5 | ||||||

| DMC1300 | C | 200 | 16 | 200 | 150 | 180 | 200 | 230 | 310 | 390 | 22.3 | ||||

| M | 150 | 13 | 200 | 115 | 140 | 160 | 190 | 210 | 22.3 | ||||||

| F | 102 | 10 | 200 | 90 | 115 | 145 | 160 | 22.3 | |||||||

| EF | 70 | 8 | 200 | 88 | 110 | 135 | 155 | 22.3 | |||||||

| DMC1380 | C | 215 | 19 | 220 | 200 | 220 | 260 | 350 | 440 | 26.3 | |||||

| M | 160 | 16 | 220 | 155 | 180 | 200 | 220 | 26.3 | |||||||

| F | 115 | 13 | 220 | 150 | 190 | 210 | 230 | 26.3 | |||||||

| EF | 76 | 8 | 220 | 122 | 148 | 185 | 200 | 26.3 | |||||||

| DCM1650 | C | 235 | 22 | 250 | 265 | 310 | 420 | 525 | 580 | 36.5 | |||||

| M | 175 | 19 | 250 | 215 | 240 | 265 | 320 | 36.5 | |||||||

| F | 130 | 13 | 250 | 180 | 210 | 235 | 255 | 275 | 36.5 | ||||||

| EF | 90 | 10 | 250 | 148 | 178 | 200 | 220 | 36.5 | |||||||

| DMC1950 | C | 350 | 22 | 280-315 | 330 | 390 | 525 | 655 | 725 | 44.3 | |||||

| M | 203 | 16 | 280-315 | 230 | 270 | 300 | 330 | 44.3 | |||||||

| F | 140 | 13 | 280-315 | 185 | 225 | 265 | 340 | 44.3 | |||||||

| EF | 95 | 10 | 280-315 | 180 | 220 | 260 | 335 | 44.3 | |||||||